Metalock Brasil dispatched its specialized seal bonding technicians for an on-site service aboard a ship at the Mauá Shipyard in Niterói (Rio de Janeiro).

The objective of the job was to replace the Large Diameter Seal (LDS) — which protects the crane’s bearings — on the ship’s main crane with a new one. However, there was no existing device to perform the bonding of the new seal.

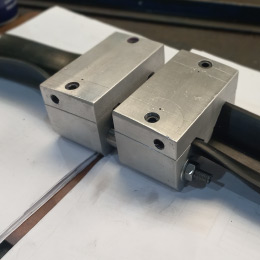

Metalock Brasil’s engineering designed and developed a device for this bonding operation, which was tested on a prototype of the seal provided by the client and a special adhesive imported from Germany.

The special adhesive was developed because the seal needed to be bonded instead of vulcanized.

Fortunately, the test was successful, and we were able to proceed with the on-site service for seal bonding.

We took measurements to cut the new seal that would be bonded and then prepared the bonding device. Subsequently, we assembled the cut seal and finally performed the bonding.

We concluded the service, which was approved by the ship’s engineers, with cleaning of the seal after bonding.

Voltar