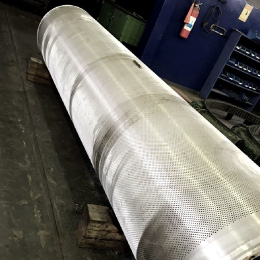

Metalock Brasil repaired an Industrial Paper Suction Roller which had already undergone repeated unsuccessful repairs.

This repaired equipment was made of stainless steel and exerts intensive forces during start-up activity, resulting in frequent internal cracks.

The machinery manufacturer made some attempts at repair through various welding procedures, but none were successful. As this manufacturer is a former customer of Metalock Brasil and had previous experience of Metalock’s excellent service provided, he indicated the Company to the Paper Mill to try to solve the problem.

Following their initial assessments, Metalock Brasil technicians identified the crack through NDT (Non Destructive Testing) Dye Penetrant test. The surface was then prepared and proceeded to repair using the exclusive Metalock® Cold Repair Process, reinforced with special Metalock® keys. This procedure is usually carried out on steel or cast iron equipment, but it has been shown to be very effective on stainless steel as well.

In just one job, Metalock Brasil satisfied two customers: the manufacturer of the Suction Roller, who recommends the Company to all their clients who use their machinery, and also the paper mill that had its problem solved on the same day.

Voltar