STRUCTURES

COMPOSITES

Engineered for the 21st Century

The world’s leading class-approved

structural repair solution

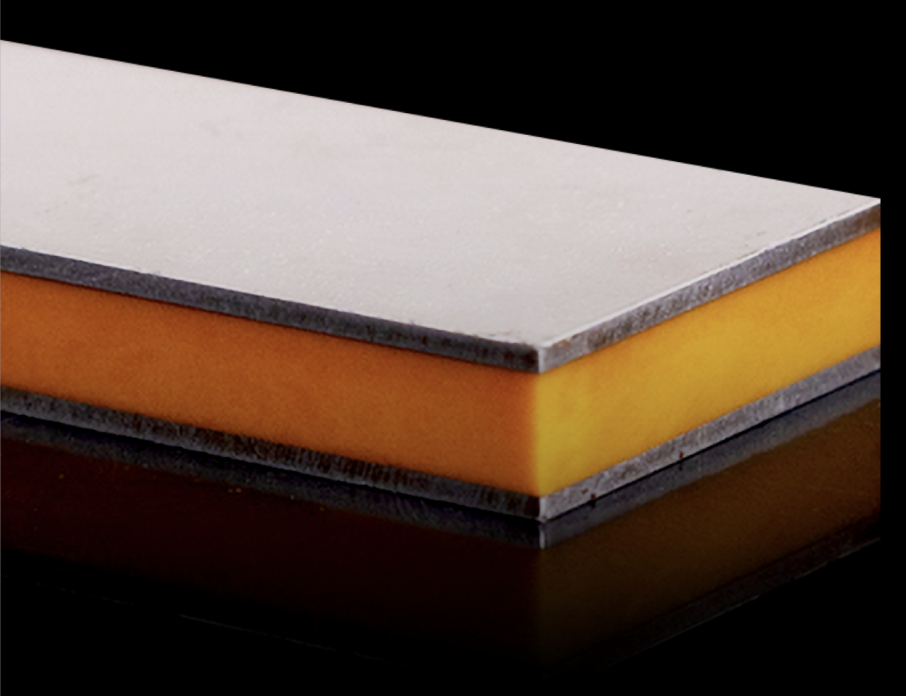

At the forefront of structural engineering, SPS Technology introduces a revolutionary solution - the Sandwich Plate System (SPS). This proprietarie structural composite material, compresed of two metal plates bonded by ElastocoreT, become a hallmark of safed, speed, durability, and strength in construction.

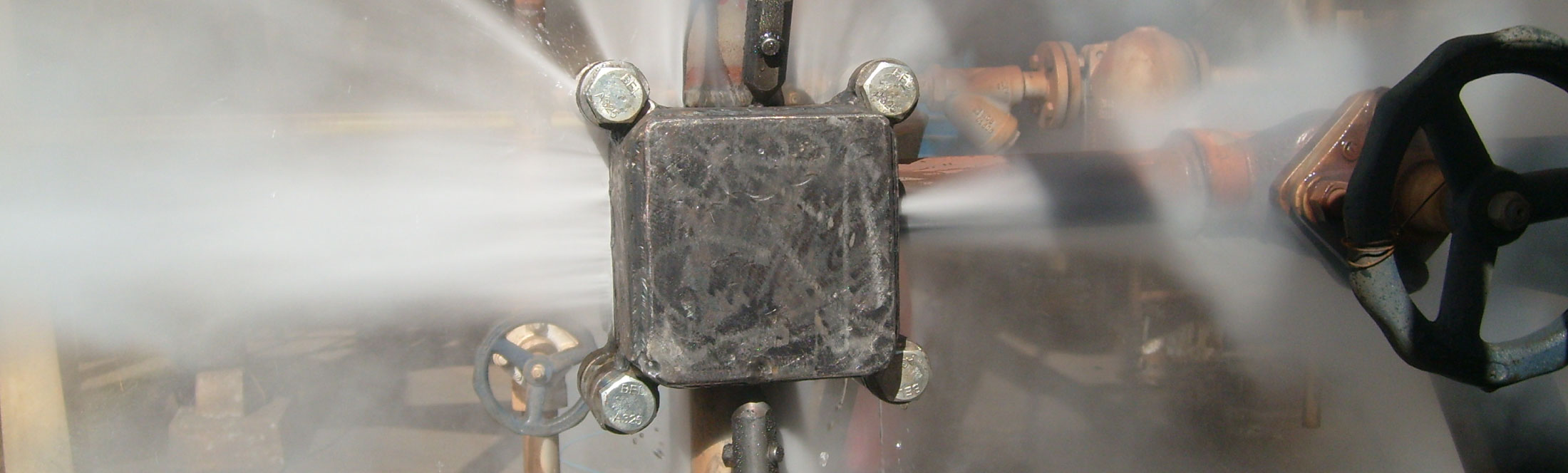

MARITIME

When it comes to strength, quality and permanence for vessel and asset repairs in the maritime industry, nothing compares to SPS.

OFFSHORE

SPS Technology and our Network Partners deliver the world’s leading Class-approved structural composite Cold Work solution for offshore repair and new builds.

SPS – the sustainable solution for Maritime and Offshore.

TRADITIONAL CROP AND RENEW:

- Requires up to 90% more labor

- Is up to 11 more expensive than SPS

- Projects are 3x slower compared with SPS

- Might need dive boats and underwater cofferdams

- Does not allow work in adjacent areas to continue in parallel

- Lengthens project schedules if services need dismantling

ALL OF WHICH ADDS UP TO A LOT OF CARBON EMISSIONS.